Mechanical brakes adjustment guide

With a brand new bike, a small amount of brake rubbing and noise can occur during a break-in period known as bedding-in new brakes. If your brakes are new, click HERE to complete the bedding-in brakes process. Rubbing and noise will often resolve over time with normal brake use (after about 25-50 miles). Ebike brakes and components may wear out faster than would be the case for non-motorized bicycles, requiring more service. If you are experiencing brake noise after the break-in period (25-50 miles), follow the steps in this article to adjust the brakes.

The brake adjustment will involve:

- Checking the wheel to make sure it is fully seated in the frame dropouts. An improperly seated wheel can cause the brake rotor on the wheel to rub on the brake pads and cause noise.

- Checking that the brake rotor is true (straight) and in good condition. A damaged or dirty brake rotor can lead to reduced brake performance or noise.

- Centering the brake caliper by adjusting the positioning so the inner pad, which is a stationary component of the brake caliper, is close and parallel to the brake rotor. A brake pad or brake caliper that is not properly positioned can lead to reduced brake performance or noise.

- Adjusting the brake cable tension and checking the brake lever feel. These final adjustments will help ensure the brakes were adjusted correctly.

These instructions only apply to mechanical brakes. For instructions on how to adjust hydraulic brakes found on the RadCity 5, RadRover 6 and RadRunner 3 Plus models, click HERE.

Tools Needed:

- 5 mm Allen wrench

- Torque wrench with a 5 mm Allen bit

- 18 mm wrench

- Torque wrench with an 18 mm socket head (or long socket head, depending on your bike model)

- Flat side cutters

- A sheet of paper

- Wooden blocks (to support the handlebar grips and protect the display if working on the bike upside down)

- Rear brake inner pad adjustment tool from Rad Power Bikes (for 2019 and earlier RadCity, RadCity Step-Thru, and RadWagon models. Contact us to order the tool, if needed)

The hardware or tool needed for your model may be slightly different. Make sure you use the correct tool and size for your bolts. Always make sure the tool is pressed firmly into the bolt head and turned slowly to prevent damaging the bolt.

- Get the bike ready for maintenance. Turn off the bike, remove the battery, and press and hold the MODE or power button to discharge remaining power.

- Identify which brake needs to be adjusted. Keep in mind that the left brake lever controls the front brake and the right brake lever controls the rear brake.

- Locate the barrel adjusters at the brake lever and brake caliper.

- Adjust the barrel adjusters so they are fully threaded into the brake lever body and brake caliper. Loosen the lockring away from the lever body, then twist the barrel adjuster toward the lever. Repeat with the barrel adjuster at the brake caliper until the barrel adjuster is fully threaded into the brake caliper.

- Check that the wheel is fully seated in the dropouts, centered with the bike, and that the quick release lever is properly tensioned. A loose wheel, or one that is not centered in the fork dropouts, can cause brake noise when the brake rotor rubs on the brake pads as the wheel spins. If the wheel is not fully seated in the dropouts or centered with the bike, follow the steps below to adjust the wheel.

- To adjust the front wheel:

- Open the quick release lever.

- Turn the thumbnut on the other side of the quick release lever counterclockwise to create more space for the fork dropouts.

- Reposition the wheel so the axle is in line with the fork dropouts. Ensure the wheel is centered, and carefully lower the bike onto the wheel axle.

- Leave the quick release lever open and turn the thumbnut clockwise until the lever can stay parallel to the ground without being held. Ensure the wheel axle is still fully seated in the fork dropouts.

- Close the quick release lever fully. This will require enough pressure that it leaves an imprint on your hand.

.gif?revision=1)

- Open the quick release lever.

- To adjust the rear wheel:

- Flip the bike upside-down. Set the handlebar grips on the blocks to protect the display from damage while performing maintenance.

-1.gif?revision=1)

- Use an 18 mm wrench to loosen (but not remove) the axle nuts on both sides of the wheel.

.gif?revision=1)

- Adjust the wheel carefully so the axle is level and fully seated in the dropouts.

- Use an 18 mm wrench to tighten the axle nuts. Torque both axle nuts to the value listed in your Owner's Manual.

- Flip the bike upside-down. Set the handlebar grips on the blocks to protect the display from damage while performing maintenance.

Once the wheel is fully seated in the dropouts and centered, continue to the next section to check the condition of the brake rotor.

| Do not touch the brake rotor, which has sharp edges and can cause serious injury. Touching the brake rotor or brake pads with bare skin can also transfer natural oils. Oils or other lubricants can decrease braking performance. We recommend wearing protective gloves when working near the braking system. |  |

- Position the bike so you can easily see the brake rotor in between the brake pads.

To check the front brake rotor, prop the bike on the kickstand so the front wheel is off the ground. Have a friend stabilize the bike, if needed.

To check the rear brake rotor, flip the bike upside-down and set the handlebar grips on the blocks to protect the display and controls, or have a friend stabilize the bike upright. - Spin the wheel to check if it spins freely. There will be little to no contact between the brake pads and brake rotor. Make sure you do not touch the brake rotor at any time, especially when the wheel is spinning.

- While the wheel spins, check the condition of the brake rotor. Place a sheet of paper behind the brake caliper to help make it easier to see if the brake rotor is true (spinning straight). If the brake rotor wobbles at the brake caliper or is damaged, it may need to be replaced. Contact us for more help.

- Use the brake lever to stop the wheel. Squeeze the left brake lever if testing the front brake and right brake lever if testing the rear brake.

Once you have confirmed that the brake rotor is in good condition, continue to the next section to center the brake caliper.

- While the wheel spins, check the condition of the brake rotor. Place a sheet of paper behind the brake caliper to help make it easier to see if the brake rotor is true (spinning straight). If the brake rotor wobbles at the brake caliper or is damaged, it may need to be replaced. Contact us for more help.

- Create brake cable slack at the brake caliper. Use a 5 mm Allen wrench to loosen (but not remove) the cable pinch bolt. Let some brake cable slide through the cable pinch bolt to create cable slack, then tighten the bolt.

- Loosen (but don’t remove) the brake caliper mounting bolts about one quarter of a turn, just until you can wiggle the brake caliper slightly.

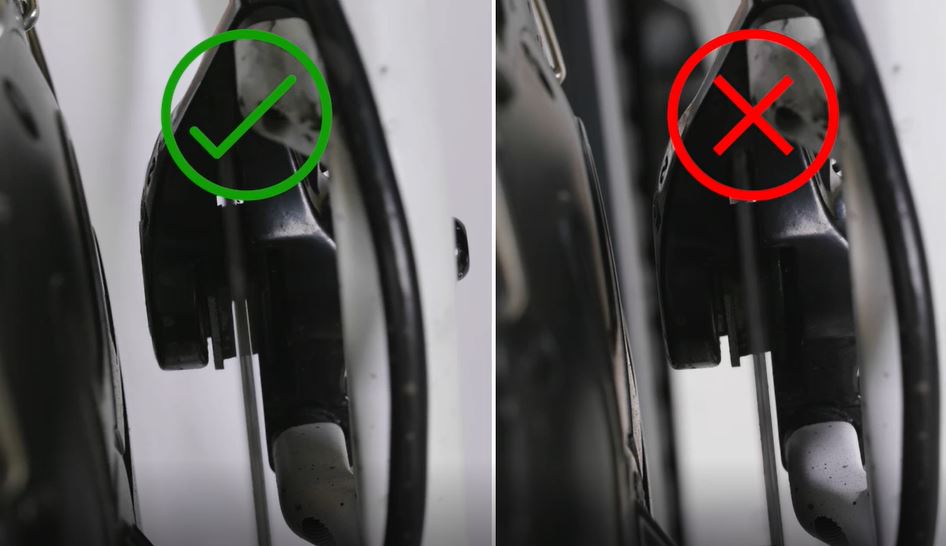

- While looking at the brake caliper from above, check how close the brake pads are to the brake rotor. If it looks like the left side of the image below, the brake rotor is appropriately spaced between the brake pads. If it looks like the right side of the image below, the brake pads are too close to the brake rotor and need to be adjusted by following the next step.

- Adjust the spacing between the brake pads and brake rotor, if needed. Use a 5 mm Allen wrench or the inner pad adjustment tool from Rad Power Bikes (if adjusting the rear brake on a bike with a direct drive motor), to turn the silver dial on the brake caliper, known as the inner pad adjustment dial, counterclockwise, or “out” to increase the space between the brake pads and brake rotor.

- Wiggle the brake caliper slightly so the inner pad is as close and as parallel to the brake rotor as possible, then tighten each brake caliper mounting bolt just until snug.

- Check that the inner pad is still parallel to the brake rotor. Hold a sheet of paper behind the brake caliper to help make the space between the inner pad and the brake caliper easier to see, if necessary.

- Repeat steps 3-6 until the brake caliper is properly centered. This may take several tries as you adjust each end of the brake caliper by tiny increments and then check how close and parallel the inner pad is to the brake rotor. Once the inner pad is in the correct position, continue to the next step.

- Spin the wheel and check if the spacing between the brake pads and brake rotor is adequate when the wheel is moving. Once the brake caliper is adjusted, torque both brake caliper mounting bolts to the values listed in your Owner's Manual.

Once the brake caliper is centered, continue to the next section to adjust the brake cable tension.

- At the brake caliper, turn the barrel adjuster out a couple of turns. Loosen the lockring on the barrel adjuster, rotate the barrel adjuster out or away from the brake caliper body, and tighten the lockring. This will help prevent overtightening the brake cable.

- Use a 5 mm Allen wrench to loosen the cable pinch bolt part way, just enough to allow the cable to move. Gently push the brake caliper arm up the brake cable while pulling the brake cable downward so it is taut. Tighten the cable pinch bolt to secure the brake cable, and torque to the value listed in your Owner's Manual.

- Spin the wheel to check if the wheel spins freely. Note that the rear wheel may have more drag and not spin as freely as the front wheel because of the motor. If the wheel does not spin freely, loosen the lockring and barrel adjuster a couple of turns counterclockwise, then tighten the lockring. This will increase cable tension and prevent the outer pad from being overtightened.

- Spin the wheel to check the clearance. If the brake rotor is rubbing against the brake pads, turn the inner pad adjustment dial counterclockwise or “out” 1 to 2 clicks to increase the space between the inner pad and the brake rotor.

To access the rear inner pad adjustment dial on a bike with a geared hub motor: pass a 5 mm Allen wrench through the spokes and into the inner pad adjustment dial.

To access the rear inner pad adjustment dial on a bike with a direct drive motor, pass the inner pad adjustment tool in between the motor and brake caliper, and into the inner pad adjustment dial.

- Once the inner pad has been adjusted, spin the wheel again to check the clearance. Repeat the adjustment as needed. Flip the bike upright, if needed.

- With the bike upright, squeeze each brake lever to check the distance between the handlebar grip and the brake lever. The lever reach must be comfortable for your hand size, but not so tight that there is no space between the lever and handlebar grip. If the brake feels loose or if the brake lever can be squeezed close to the handlebar grip, the brake cable likely needs more tension. Continue to the next step to increase cable tension.

- To add more tension to the brake cable, locate the barrel adjuster at the loose lever and the corresponding brake caliper.

- Loosen the lockring and rotate the barrel adjuster “out” in small increments so it moves away from the lever. Tighten the lockring. This will increase cable tension.

- Spin the wheel again to check for clearance between the brake pads and brake caliper. Squeeze the brake lever to stop the wheel. If more tension is needed, loosen the lockring, twist the barrel adjuster farther away from the lever body, and tighten the lockring. Spin the wheel again and squeeze the brake lever to stop the wheel.

- If the brake still feels loose, increase cable tension at the brake caliper. Loosen the lockring and turn the barrel adjuster “out” or away from the brake caliper. Tighten the lockring. Spin the wheel, squeeze the brake lever to stop the wheel, and repeat the adjustment if needed.

- Loosen the lockring and rotate the barrel adjuster “out” in small increments so it moves away from the lever. Tighten the lockring. This will increase cable tension.

- Spin the wheel to check if it spins freely.

If the wheel spins freely with adequate clearance between the brake pads and brake rotor, the brakes have been adjusted.

If the issue continues or the brake rotor looks like it gets twisted when the brake is squeezed, further adjustments are needed. Contact us for more help. - Reinstall the battery, test the bike fully before riding, and ride Rad!

To get the most life out of your brakes, use both the front and rear brake together, and always engage the rear brake first to prevent excessive strain on the front wheel and fork and to prevent loss of control.